Azure IoT Edge, Hybrid + Multicloud, Internet of Things, Thought leadership

Build secure manufacturing operations with nesting capabilities for Azure IoT Edge

Posted on

4 min read

The manufacturing industry continues to rapidly adopt Internet of Things (IoT) technology to optimize productivity, gain efficiencies, increase uptime, and meet sustainability goals. As organizations look to harness IoT across their ecosystems of connected devices, security and compliance continue to be at the forefront of conversations.

Our commitment is to simplify IoT for mainstream adoption. As such, we are announcing the general availability of nesting capabilities for Microsoft Azure IoT Edge that conforms to ANSI/ISA-95 standard for network isolation. This IoT Edge solution adds to other significant advancements that make it easier for companies to benefit from IoT, including Azure Defender for IoT, Azure IoT Edge security enclaves, Device Update for IoT Hub, and Azure Digital Twins.

Unlocking value with nested Azure IoT Edge devices

Smart manufacturing faces a dilemma: manufacturers want to improve operational excellence by using modern cloud-scale solutions, such as artificial intelligence (AI)-powered predictive maintenance. Yet, they often cannot easily connect industrial systems to the internet due to security and safety concerns. For years, network segregation within a facility has been a security principle recommended by the ANSI/ISA-95 standard, which is widely adopted across industries with high-security requirements to prevent potentially dangerous breaches. But that meant on-premises network segregation with the cloud was not possible—until now.

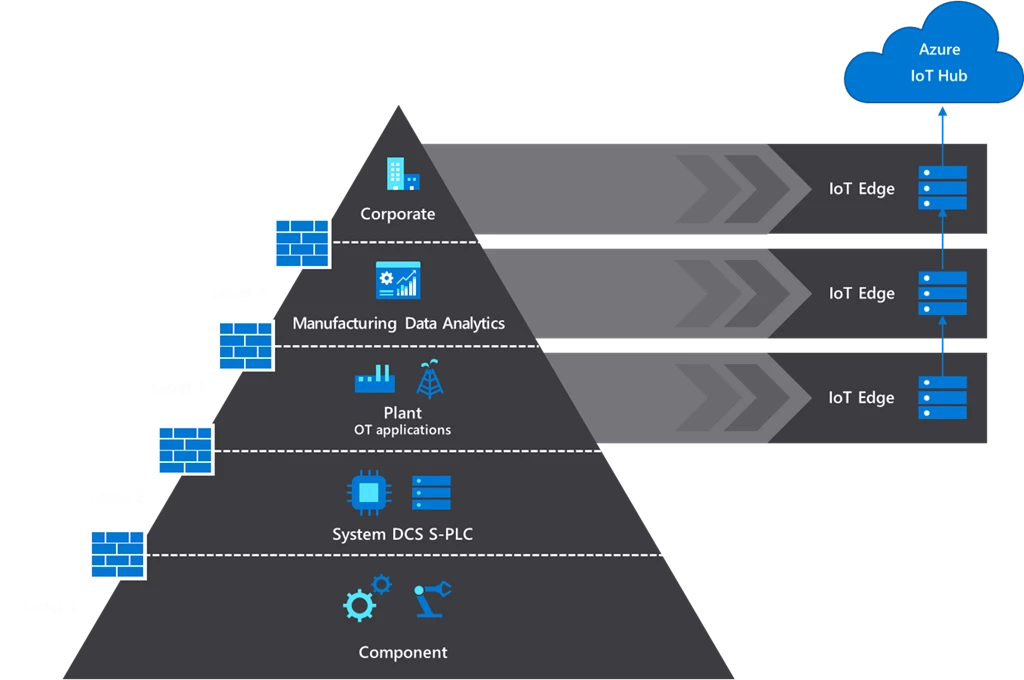

By enabling hierarchies of IoT Edge devices through the automation pyramid, manufacturers can collect data from their systems, aggregate it, and forward it to the cloud without compromising their systems. The device management and communication functionalities of a single IoT Edge device have also been extended to work through hierarchies of IoT Edge devices.

Figure 1: Hierarchy of IoT Edge devices to extract data from the automation pyramid

Unleashing the power of threat intelligence at the Edge

Azure Defender for IoT can work in tandem with the nesting capabilities for IoT Edge to bolster security. It is a practical, agentless network-layer solution for securing both brownfield and greenfield IoT/OT environments from the growing threat of cyberattacks that can take down production, steal sensitive intellectual property, and cause safety and environmental incidents. It continuously monitors industrial networks for threats, anomalies, or unauthorized activities with no impact on the network or reliability.

Using nesting for IoT Edge to improve operations

Some of the world’s largest manufacturers, like Tetra Pak, Toyota Industries, and Softing Industries, are already examining hierarchies of IoT Edge devices to deliver additional value through layered networks.

Tetra Pak expands digital services with hierarchies of IoT Edge devices

Tetra Pak, a pioneer in the food and packaging industry with a focus on sustainability, innovation, and quality, is using the Azure IoT platform to offer new services and improve customers’ operations. Central to the new Tetra Pak digital platform is establishing robust and secure connections between production networks and the cloud for the transportation of machine data and orchestration of applications running at the edge. Tetra Pak, which relies on the new nesting capability of IoT Edge to comply with customers’ policies and layered networks, is an early adopter that collaborated with Microsoft on the technology design and testing.

“The solution that we can get from IoT, and the new nesting capability for Azure IoT Edge devices, will allow us to expand our capabilities with our customers to deliver even more value.”—Magnus Wijk, System Architect IIoT, Tetra Pak.

Toyota Industries expands capabilities of companywide IoT platform

Toyota Industries operates in various manufacturing-related businesses and built GAUDI, a companywide standardized IoT platform to collect, store, and analyze data. As part of its commitment to continually improve manufacturing sites, the company established an AI-based mechanism for detecting signs of faults from equipment data and returning the optimal parameters.

In alignment with their strict networking requirements, Toyota Industries is looking to utilize nested edge capabilities to build a multi-layered structure between their factory and corporate networks.

Softing Industries increasing the possibilities of manufacturing data integration

As a Microsoft partner, Softing specializes in the connectivity of products and solutions for OT/IT integration. Supporting container technology, its products such as edgeConnector Siemens can be deployed on Azure IoT Edge and fully managed via the Azure platform. The components typically need to run inside the automation network on a lower network level in a layered topology. Azure IoT Edge support for nested topologies allows Softing customers to manage the company’s components in an efficient way, even if the components don’t have direct internet connections.

“Our connectivity products seamlessly integrate with Azure IoT Edge. With nested network topologies within the Azure IoT framework, we can continue to bring secure and scalable data integration to our customers.”—Dr. Christopher Anhalt, VP Product Marketing, Softing Industrial

Use nesting capabilities for IoT Edge to harness benefits of IoT

Nesting capabilities for IoT Edge adds to the security-focused, flexible solutions Microsoft offers for industrial IoT users. Join us at Hannover Messe on April 12-16 to learn how Azure IoT products and services are helping simplify the process of connecting, managing, and securing IoT devices and empowering organizations to succeed with IoT.

Partners and customers can learn more about this new solution from this nested IoT Edge tutorial and sample on GitHub.

Additional IoT in manufacturing resources

- Learn more about Microsoft Cloud for Manufacturing.

- See the latest manufacturing insights in the Microsoft IoT Signals report.

- Read the Intelligent manufacturing white paper.

- Hear from manufacturing customers and partners in the What I Wish I Knew video series.

- Simplify device integration with IoT Plug and Play.

- Certify your devices for industrial IoT solutions via the Azure Certified Device program.