Technology has enabled some pretty amazing things, but being in two places at once still isn’t one of them. Fortunately, the Internet of Things (IoT) has enabled companies to use and share their expertise more efficiently, increasing productivity without needing to increase manpower.

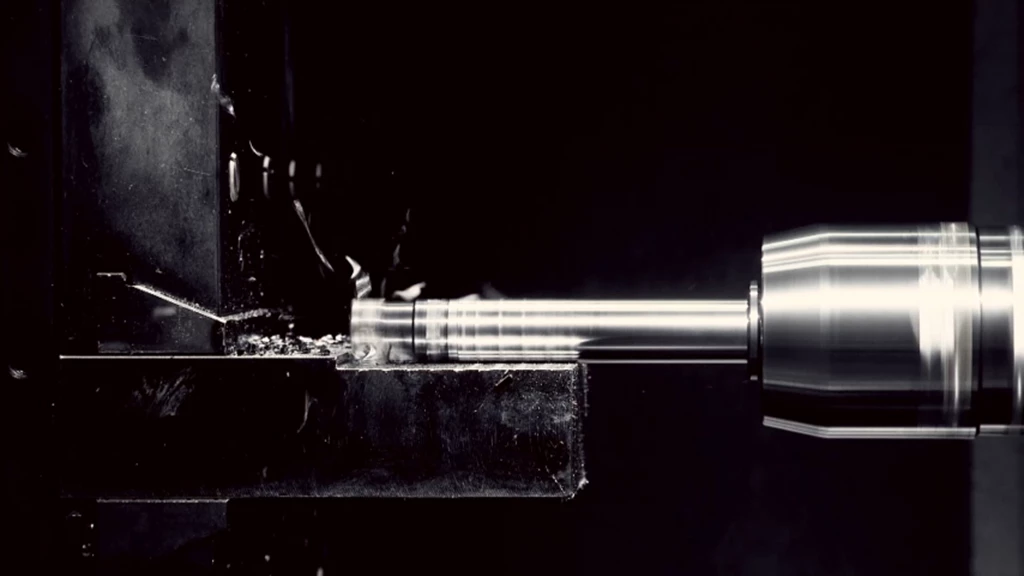

Take Sandvik Coromant, for example, part of the global industrial group Sandvik. Sandvik Coromant as a global market leader has developed extensive know-how within tooling and the manufacturing industry over many decades. Since the emergence of digital solutions within manufacturing, Sandvik Coromant successfully transferred this knowledge also to the so-called “digital manufacturing”.

Sandvik Coromant has always been committed to the pursuit of technological development, and believes in working closely with manufacturing customers to provide reliable tools and tooling solutions. That dedication is embodied by a team of “yellow coats,” technical experts with extensive expertise who provide training and troubleshooting to customers in more than 150 countries. In addition to helping customers remotely and at Sandvik Coromant Centers, “yellow coats” also conduct on-site visits, where they can make adjustments as needed and provide recommendations to improve the customers’ manufacturing process.

Continued growth created a new challenge for Sandvik Coromant, however—even its “yellow coats” couldn’t be everywhere at once. The question was how to scale the team’s services quickly, without having an impact on quality?

IoT provided the answer. Advances in composite materials, and the benefits of sensors and other IoT technologies have prompted many manufacturers to retool for the realities of “Industry 4.0”. Sandvik Coromant has taken this opportunity to create a scalable service model that delivers the same world-class quality of service and technical expertise that its customers are used to, still having “yellow coats” available when needed.

Using Azure IoT Suite, Cortana Intelligence and Dynamics 365, Microsoft helped Sandvik Coromant to develop its service model with a predictive analytics solution that ties all of the elements of the supply chain and fabrication process together.

IoT Suite collects, computes and analyzes data from sensors embedded in all of the tools across the shop floor, monitoring every aspect of their performance, as well as the existence of any bottlenecks in the overall supply chain or manufacturing. Then, with Cortana Intelligence, Sandvik Coromant takes that analysis and makes recommendations on how to optimize the manufacturing process, and creates a predictive maintenance schedule that’s designed to help avoid unscheduled shutdowns. Finally, the solution integrates master data from the CRM system with meta data from the shop floor system and the machining system and makes them available through CRM to Sandvik Coromant which can then provide feedback and then support in predicting when to change or order a tool.

“Through our close partnership with Microsoft, we have developed the new predictive analytics manufacturing solution connects an in-house shop floor control tool that collects all the information, such as machine data, tool data, and sends it to Azure for real-time analysis using Machine Learning algorithms to optimize the process in real-time and set up predictive maintenance schedules and set alarms so that we can know when to take a machine offline before a failure occurs. In the end, our customers will be able to make quicker and better informed decisions to become more profitable” says Nevzat Ertan, Chief Architect & Senior Manager, Sandvik Coromant.

With this technology, Sandvik Coromant has digitized its deep expertise and provides services that help customers make more informed decisions, and more easily calculate the financial return on a new machining tool. That translates to additional revenue, happier customers and greater flexibility in how its technical experts connect with customers.

Read the Sandvik Coromant customer story to learn more about the company’s predictive analytics solution. Learn how IoT can transform your business today.