Azure IoT

Connect, monitor, and control devices and assets with secure cloud-to-edge solutions.

Bring intelligence to physical products, operations, and experiences

Liberate your data at the edge, efficiently secure and manage your cloud assets, and proactively make decisions across your entire enterprise.

Accelerate digital transformation by building a data foundation for AI, enabling collaboration across IT and operational technology (OT), and ensuring solutions are interoperable and scalable.

Connect and secure billions of devices and gain actionable insights with a collection of services across the edge and the cloud, including security and analytics capabilities that help businesses build, deploy, and manage IoT platform applications.

Visualize physical operations data and simulate processes. Explore, report, and analyze OT data from your physical environment with context from the rest of your enterprise IT data in the cloud.

Build scalable IoT solutions

Explore the largest ecosystem in the industry

Take advantage of an ecosystem of thousands of partners to deploy hundreds of proven, repeatable solutions for your specific business needs.

Secure your environment from chip to cloud

Protect your organization on all fronts—hardware, software, and in the cloud—as you build open, flexible, and scalable IoT solutions with Microsoft Defender for IoT.

Operate from a single control plane

Streamline operations with unified management of organizing, monitoring, and controlling devices, apps, and infrastructure.

Develop solutions with best-in-class tools

Quickly connect and monitor billions of devices on a fully managed IoT platform to innovate faster and reduce the burden of managing infrastructure.

Explore Azure IoT solution architectures

-

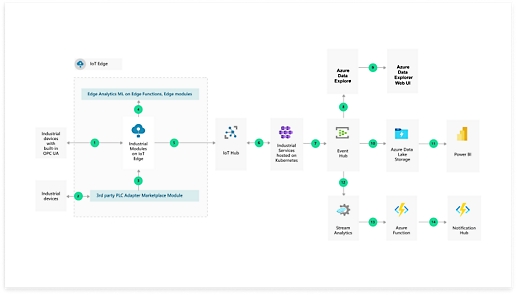

Condition monitoring for industrial IoT

Monitor your equipment's key parameters to identify significant changes and prevent unexpected failures and production disruption.

-

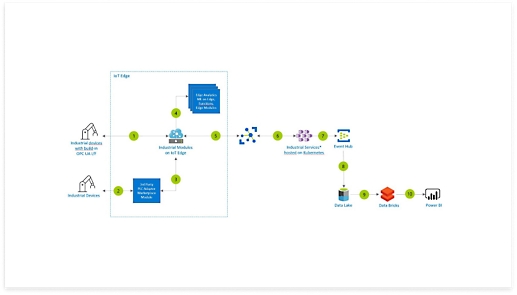

Predictive maintenance for industrial IoT

Diagnose equipment status and performance, predict potential malfunctions and maintenance needs, and utilize mixed reality and digital twins technologies to enhance service in real time.

-

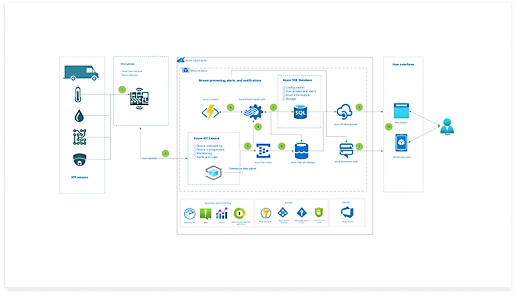

Real-time asset tracking and management

Track and manage assets in real time.

Learn more about Azure IoT products and services

Azure IoT Operations

Capture asset data, process it at the edge, and send it to the cloud with Azure Arc–enabled services

Azure IoT Hub

Connect, manage, and scale billions of IoT devices from the edge to the cloud.

Azure Digital Twins

Build next-generation IoT spatial intelligence solutions by replicating real physical spaces and creating connected environments.

Azure IoT Edge

Extend cloud intelligence and analytics by moving workloads and business logic from the cloud to edge devices.

Azure Sphere

Securely connect MCU-powered devices from the silicon to the cloud.

Windows for IoT

Long term OS support and services to manage devices.

Azure RTOS

Making embedded IoT development and connectivity easy.

Get the latest Azure IoT news and resources

To rapidly realize business outcomes, here are some key solutions readily available from partners.

Cognite Data Fusion

Rapidly empower industrial companies with contextualized, trustworthy, and accessible data.

ThingWorx Digital Performance Management (DPM)

Leverage IoT data to help identify and prioritize operational and equipment issues.

Sight Machine on Azure

Provide every stakeholder with a single trusted and dynamically updated view of production.

Factory Talk Innovation Suite

Use AI and machine learning to simplify and automate gathering and analysis of complex IT and OT data.

AVEVATM Insight

Get operations management and asset performance in one easy-to-use cloud-based solution.

Factory Digital Twins

Gain an integrated view of global factory performance with context of its commercial impact to your business.

Reflect IoD

Optimize data access, integration, and design for enhanced operations effectiveness.

Johnson Controls OpenBlue Enterprise Manager

Proactively analyze building data across your enterprise to find areas for improved performance.

Find a partner

Get in touch with trusted Microsoft partners

Start learning

Get started building end-to-end IoT solutions on Azure IoT.

Ready when you are

Let’s set up your Azure free account.

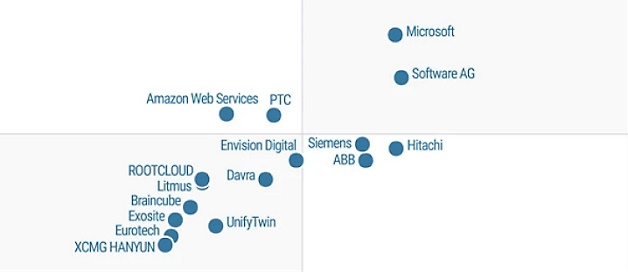

Gartner, Magic Quadrant for Global Industrial IoT Platforms, Al Velosa, Eric Goodness, et. al, December 12,2022.

Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.