Around the world, customers are demonstrating the future of data-driven manufacturing. Dutch paint company AkzoNobel transformed from a manual operation to one focused on expanding a modern digital performance solution across its European factories. Swedish manufacturer Sandvik Coromant saw a 40 percent increase in engineering and operator productivity.

How others can replicate data-driven manufacturing success

We’ve recently developed a white paper to help our customers understand how they can replicate that success in their own facilities. For manufacturers, the promise of Industry 4.0 lies in breaking down silos and gaining a holistic view across the entire operation, from asset data to insights across all manufacturing processes. However, there are some big challenges in getting there—the data path is generally several layers deep, and enabling those layers to communicate freely can be an expensive proposition.

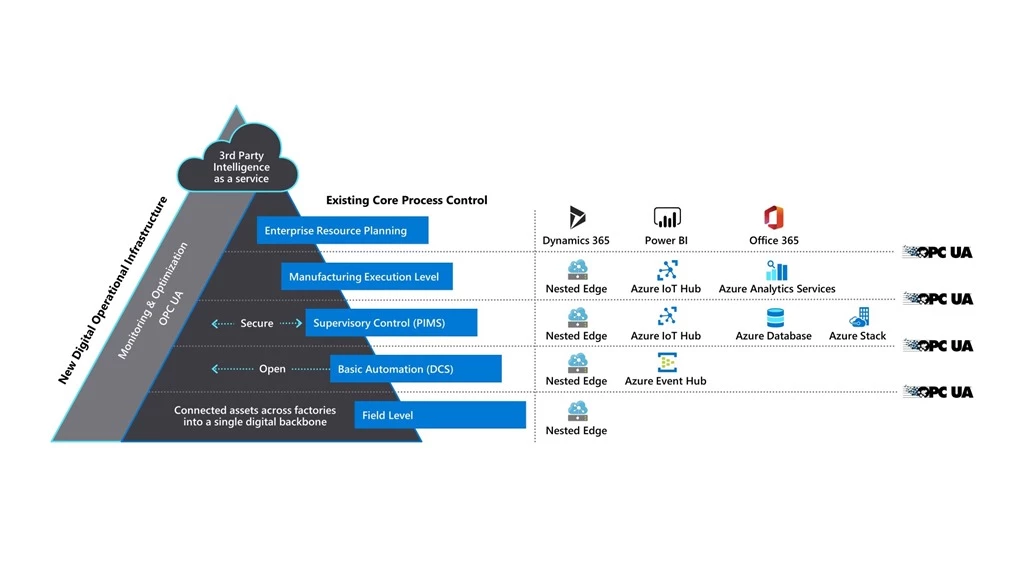

The manufacturing industry has a series of standards and compliance requirements, such as the International Society of Automation’s ISA-95. The ISA-95 automation structure is a generally accepted standard for manufacturing control systems that supports long-term reliability of operation. Still, it also makes interactions with control systems and automation devices all but impossible from an internet-connected system. However, building the capabilities from scratch to integrate the layers of the automation pyramid requires intense networking effort and expertise. Many companies are unable to fully realize their vision for a functional solution.

Microsoft Azure offers a path to overcome the ISA-95 compliance and interoperability conundrum. Azure Industrial IoT enables both established plants and new plants to be equipped with future monitoring and optimization functions for Industry 4.0 needs, in addition to the classic automation pyramid—through a safe, secure, and open approach that does not compromise existing implementations.

Our white paper shows how customers can use an Azure nested edge solution to unlock Industry 4.0 in their own facilities. It offers guidance on how customers around the world can build cloud-native industrial solutions on their terms and be ready for the future. The Azure nested edge is your path to meeting ISA-95 requirements without getting stuck in networking limbo.

Let’s take a look at what Azure nested edge allows you to do

- Increase security and deploy edge computing at multiple levels of the automation pyramid without compromising existing technologies.

- Benefit from the increased security and compliance standards mandated by ISA-95.

- Leverage edge computing that puts managers and engineers right on the factory floor when they’re needed.

- Securely collect and aggregate telemetry from each layer of the network to reduce unplanned downtime and minimize manufacturing defects.

By adopting open standards to innovate and connect the dots between your partners’ systems and your own—while respecting the limits and requirements of the ISA-95 environment—we can help you simplify your systems so you can focus on what’s important for your business.

To learn more about this game-changing offering, take a look our white paper.